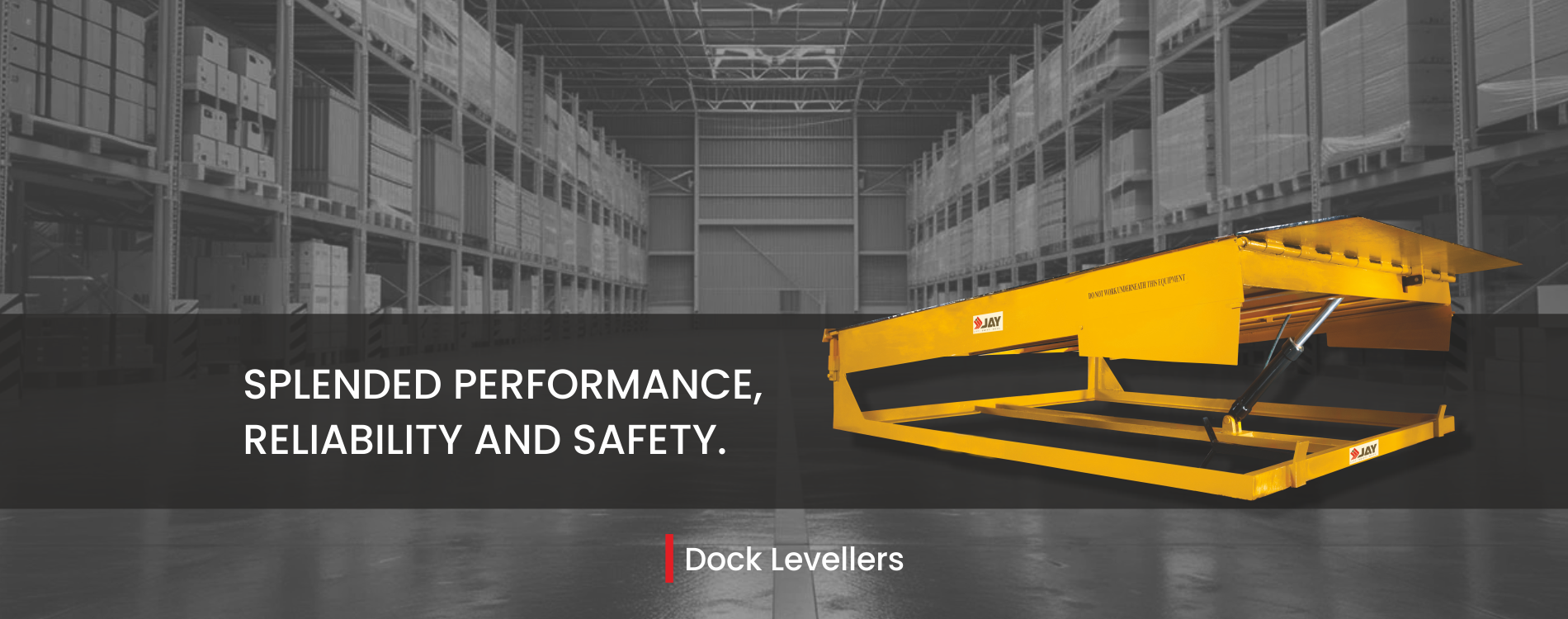

We are ISO 9001:2015 company and involves both the end to achieve desired quality. We provide our customers high quality by keeping multiple checks at various process stages from product planning to final delivery.

Well defined process including internal quality audit, experiment & review production manufacturing and collecting & responding to market information helps us to excel everytime.

At JAY, we promise competent safety. We are complying with all relevant legislation & standards like ISO 14001:2015 and applying best industrial manufacturing practices. We conduct safety training program for employees, do risk assessment and wmbrace occupational safety services for site based personnel.

Protecting, promoting and maintaining the safety of all stakeholders in its areas of operation is our key motto.

Protecting the environment, preventing pollution and ensuring rigorous controls on environmental impacts is what we believe.

We are OHSAS 18001:2007 compliant and all our equipment are battery operated & designed as per international standards and perform efficiently to suit every need.